Visions Enterprise® is the industry-leading asset integrity management solution, designed to streamline inspection, operational, and engineering data for all assets, from wellhead to shipping terminal, on a single platform. Track and manage mechanical and inspection data with ease, quickly identify and resolve non-conformances, and optimize inspection planning. Gain real-time insights into recommendation progress, inspection schedules, asset risk levels, and performance comparisons across regions, plants, and units – all from one intuitive interface.

Over 1350 facilities worldwide, spanning industries like oil & gas, chemical, and power,

trust Visions Enterprise® to enhance asset integrity management.

Maximize the lifecycle of critical equipment by improving durability, reducing wear, and preventing failures.

For over 30 years, Visions Enterprise® has consistently extended asset life, minimized shutdowns, and ensured long-term reliability for global leaders in asset-intensive industries.

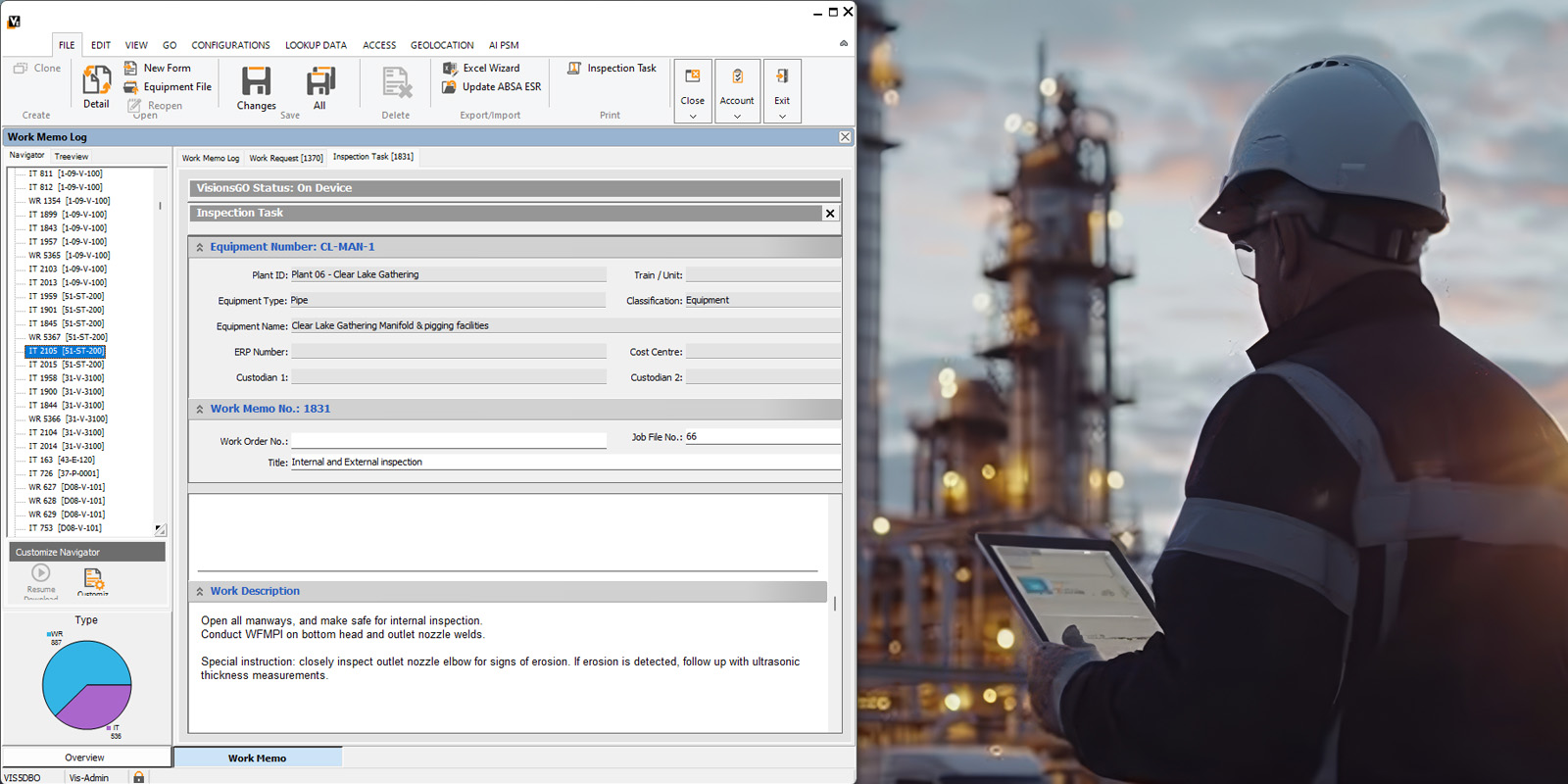

Manage fixed and rotating equipment types on a single platform, ensuring end-to-end asset integrity from wellhead to shipping terminal.

Manage fixed and rotating equipment types on a single platform, ensuring end-to-end asset integrity from wellhead to shipping terminal.

Seamless integration with SAP, EAM, and CMMS systems for enhanced connectivity across your organization.

Seamless integration with SAP, EAM, and CMMS systems for enhanced connectivity across your organization.

Achieve a 40–60% faster implementation process, minimizing downtime and accelerating ROI.

Achieve a 40–60% faster implementation process, minimizing downtime and accelerating ROI.

Prior to 2017, this major midstream operator depended on rudimentary tools such as spreadsheets and Microsoft Access databases to handle their inspection and asset integrity data.

Driven by an unwavering commitment to operational excellence, our client recognized the pressing need for a more sophisticated solution for managing complex risk assessments. Thus, they entered a strategic partnership with Metegrity, heralding a new era of risk assessment. This transformation not only advanced their digital objectives but also fortified safety and operational efficiency throughout their operations.

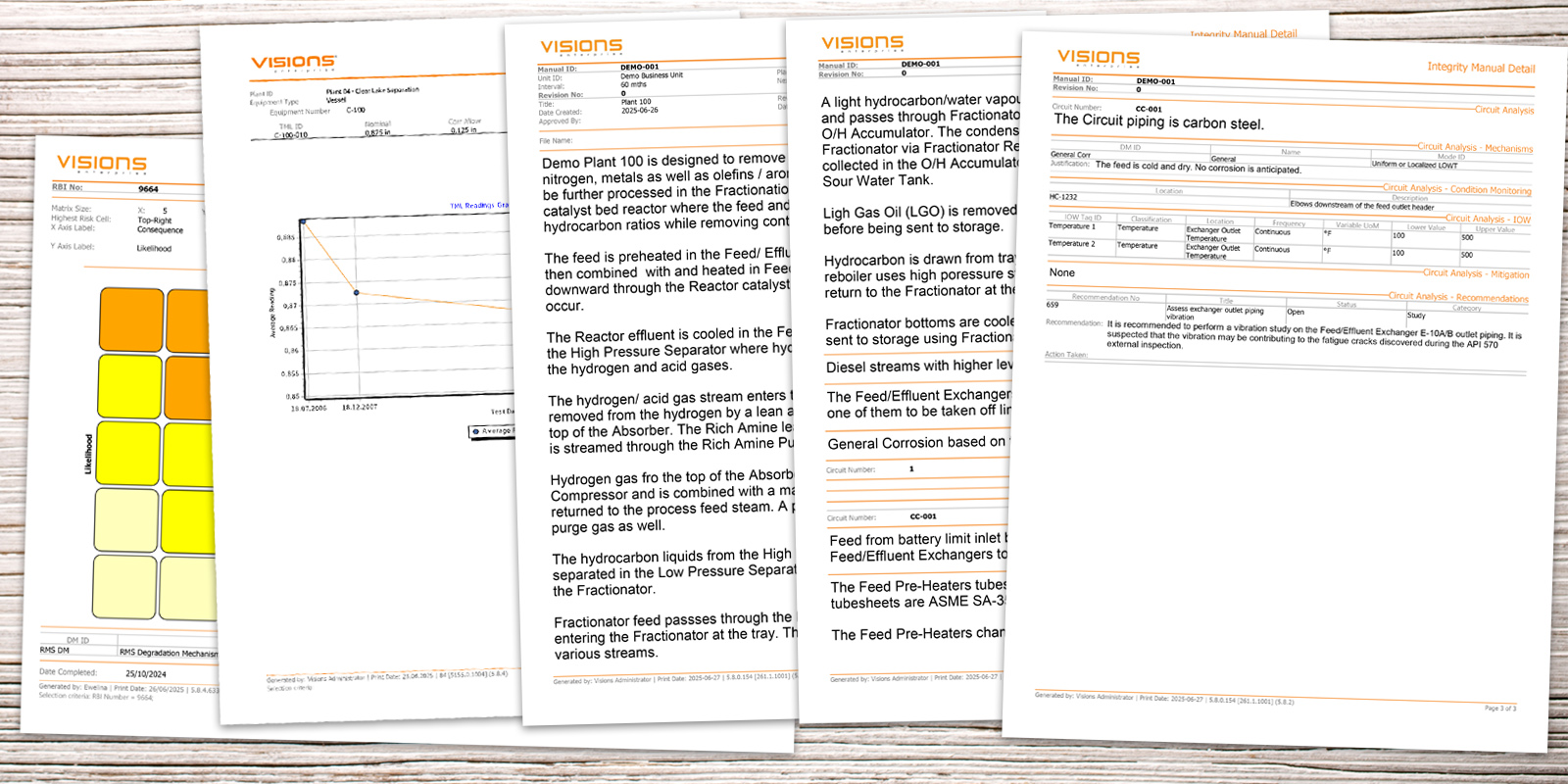

Visions Enterprise® offers a flexible modular design, starting with a core framework for equipment configuration, user management, and inspections. Build your solution by adding modules that fit your business needs.

Visions RBI enables you to focus inspection resources on critical equipment while improving reliability of equipment. It can drastically reduce inspection frequency.

This module allows you to document individual process unit corrosion analysis in a structured format. It improves understanding of the potential of acting degradation mechanisms specific to the asset.

IOW allows you to improve predictive accuracy. It monitors an asset’s operating conditions and sends early alerts if pre-defined boundaries are exceeded.

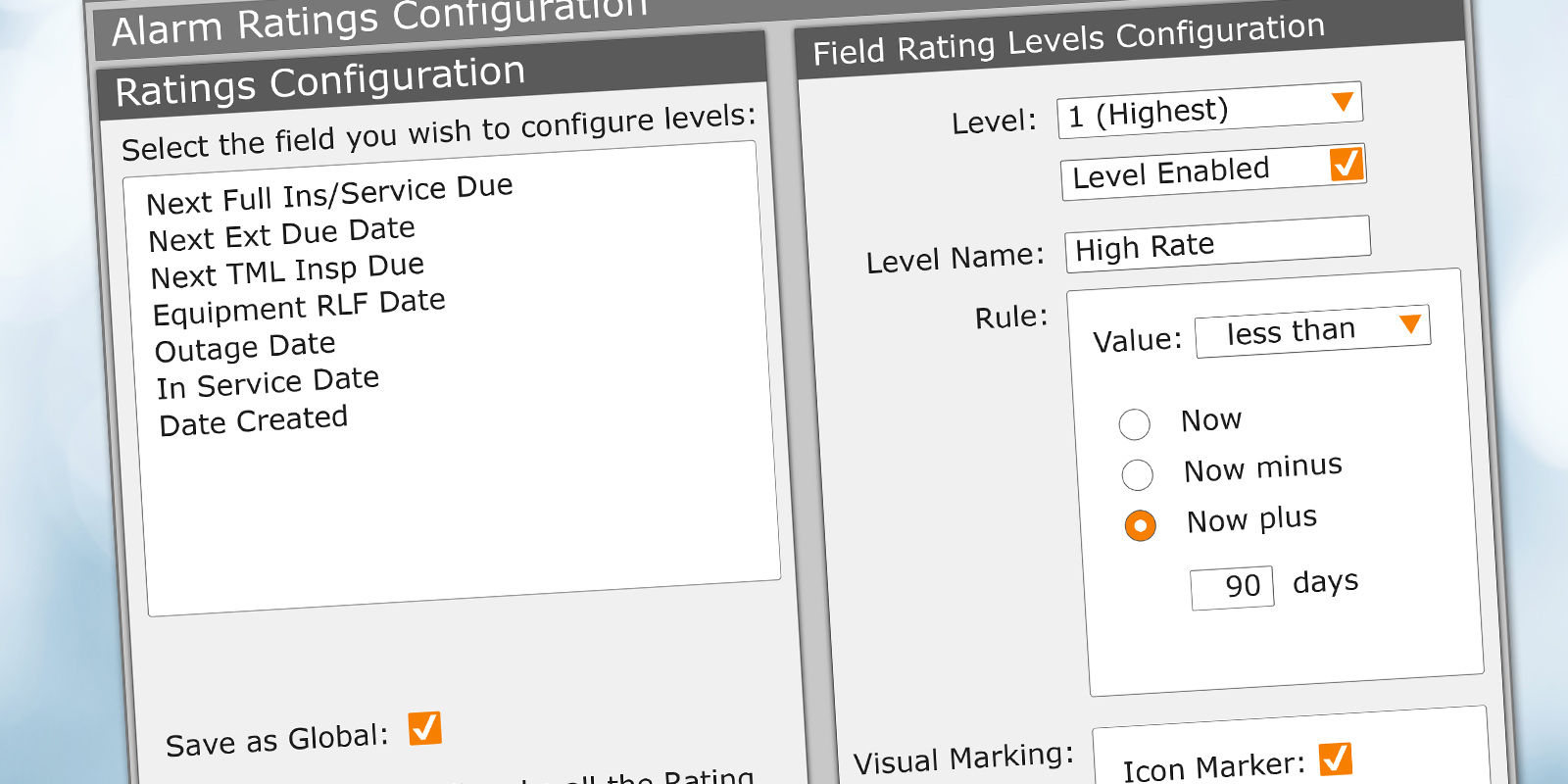

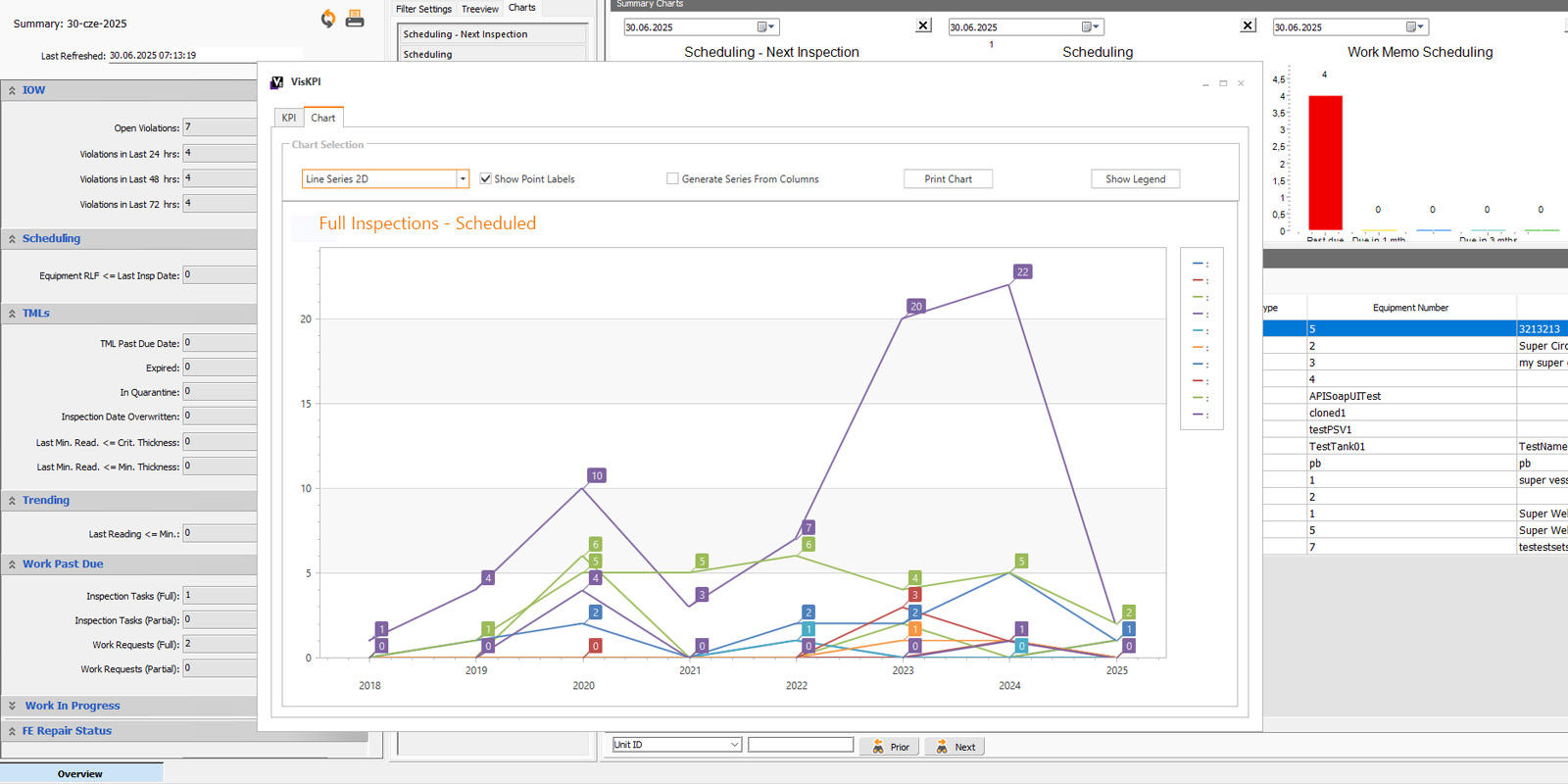

Save time with Visions’ Alarm Ratings feature, which provides a quick means of identifying upcoming scheduling.

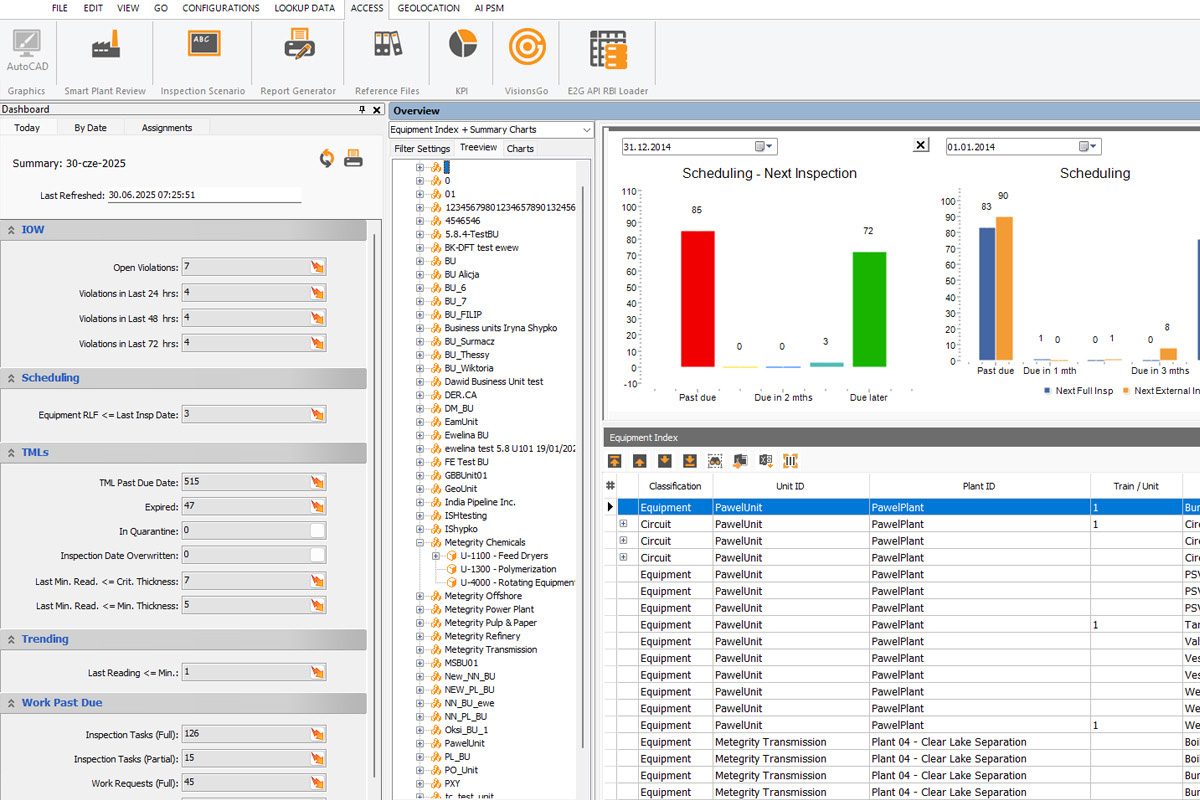

The Dashboard is an excellent, day-to-day tool for users and managers to review the status of equipment scheduling and outstanding work.

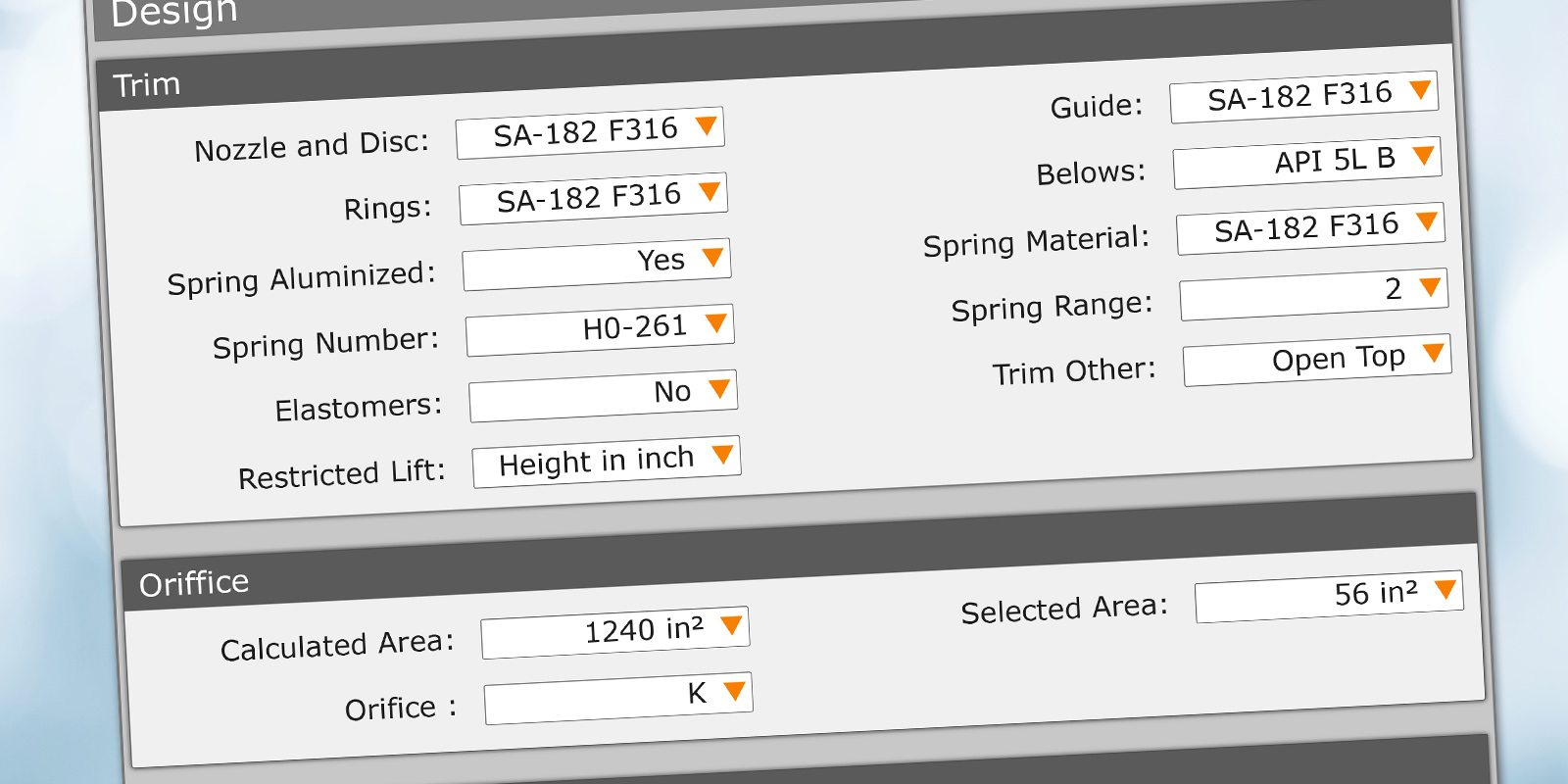

Based on ASME/API data sheets, the Design Data feature includes engineering and manufacturer data for all asset types.

Directly import and export thickness readings between datalogging gauges and Visions.

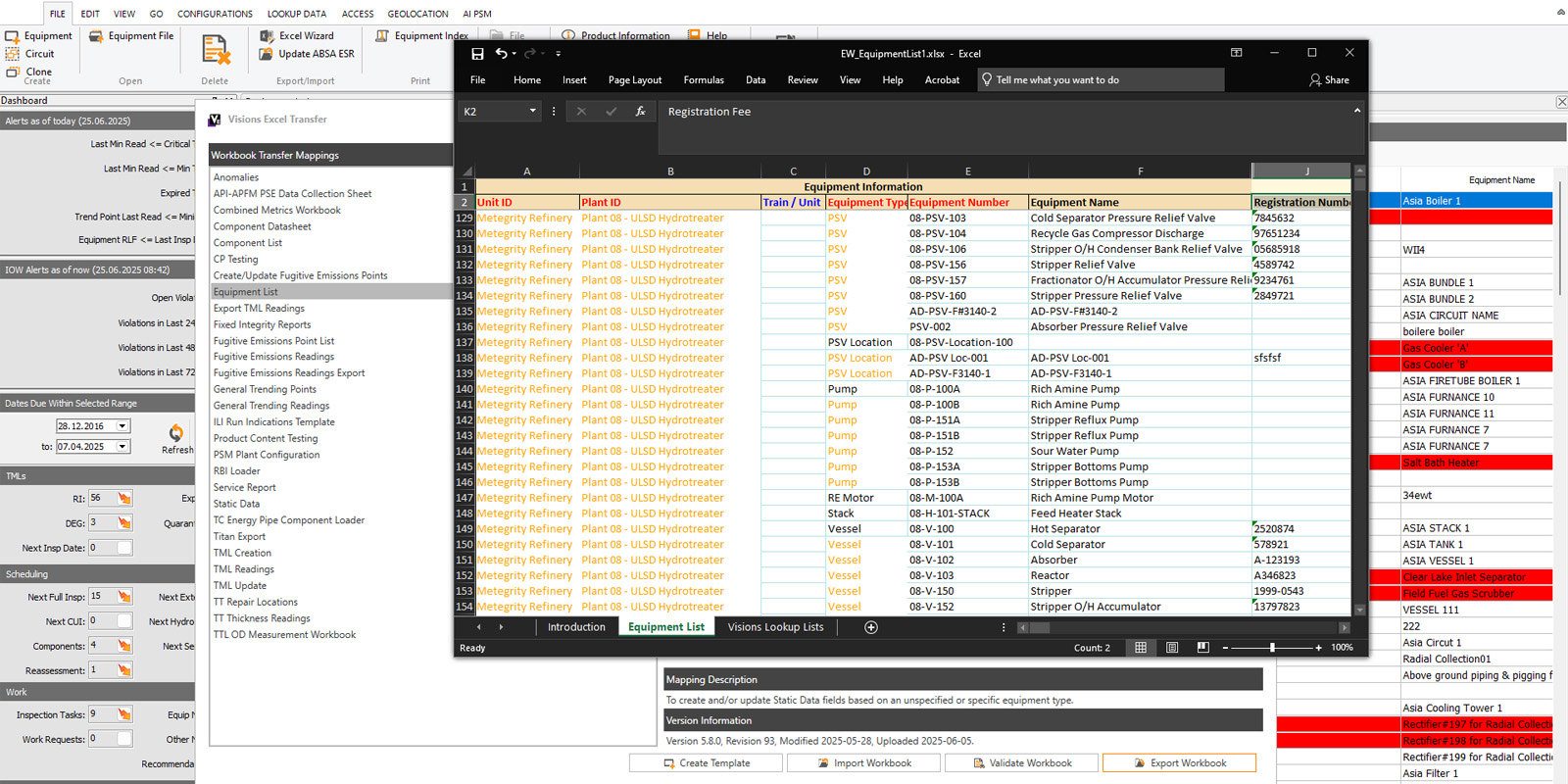

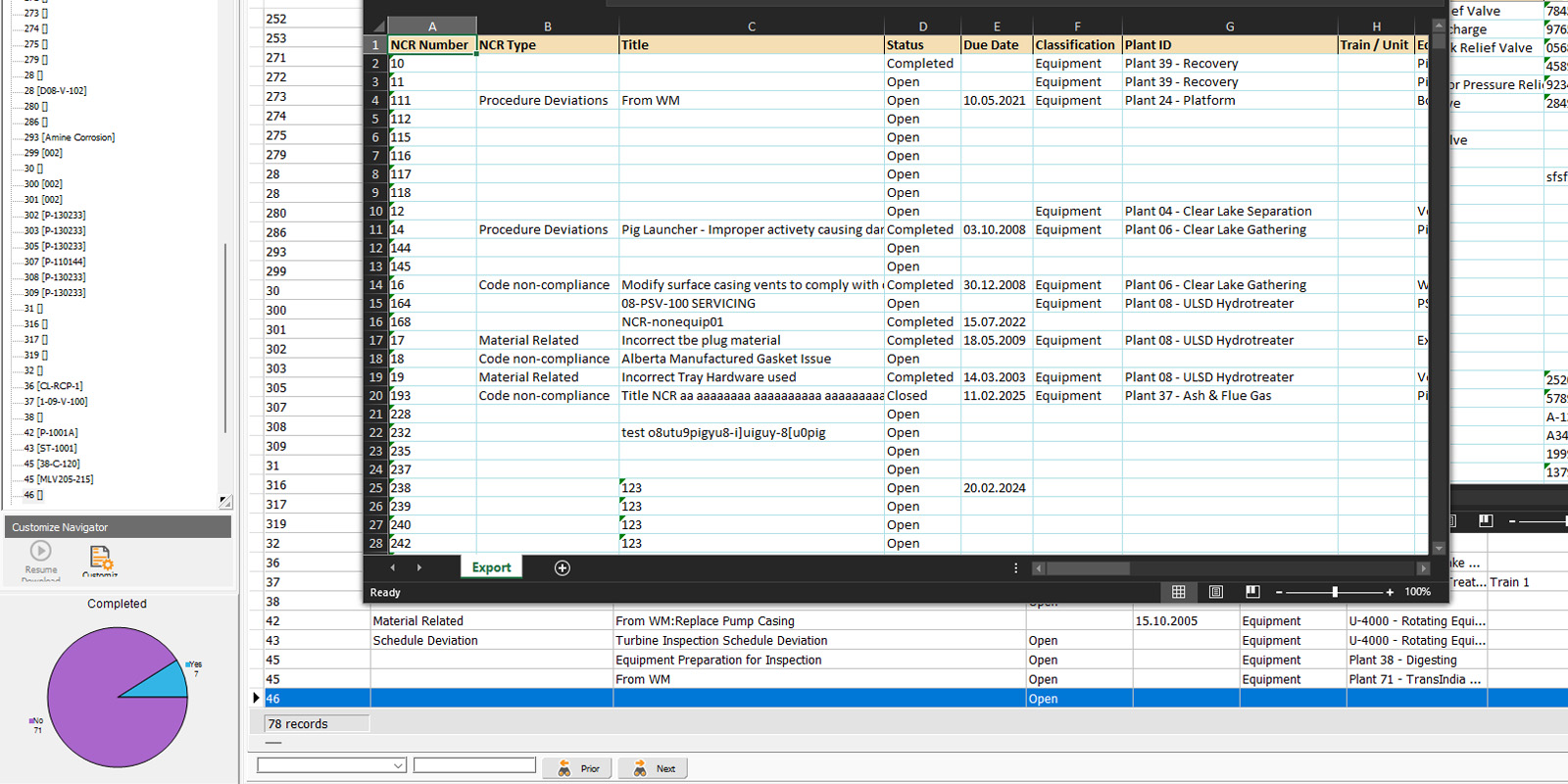

One of the most useful features, the Excel Wizard enables you to populate data in Visions directly from an Excel spreadsheet.

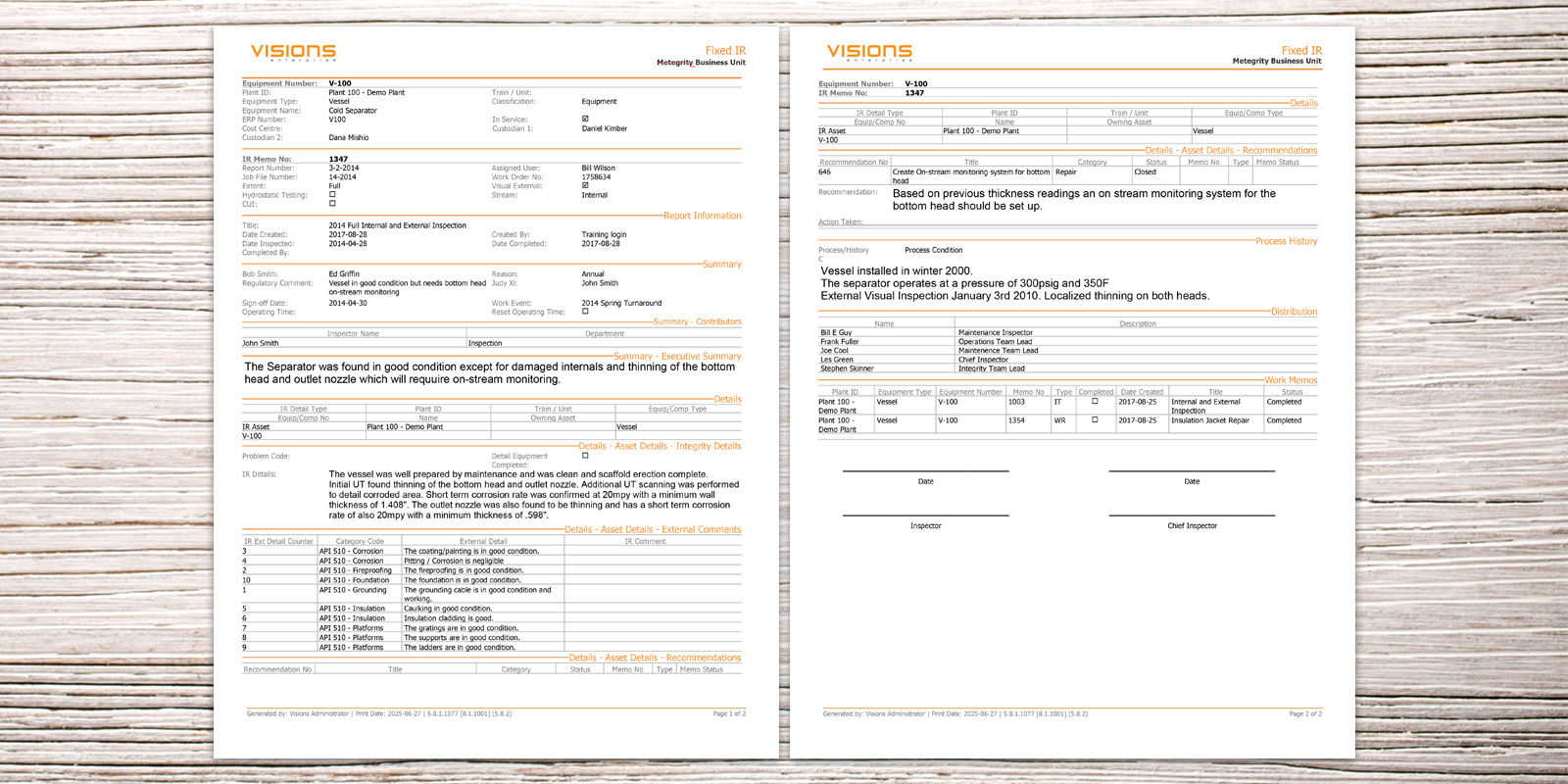

This feature provides a centralized location for inspection findings.

Visions’ KPI feature enables you to summarize key performance indicators.

Document all issues of non-conformance found during work or inspection in an easily searchable, central access point.

Define rules and receive convenient alerts according to those conditions. Being notified of user-defined changes enables you to address the change in a timely manner before a loss of containment occurs.

This feature enables you to document and quickly identify the recommendations or requirements for each asset.

Easily generate complete, configurable, current and comprehensive reports with the click of a button. This enables the user to run reports which may provide critical data in preparation for major turnarounds or to provide management with data for audits.

Protect your data with Visions’ Security feature. Controlled access translates to enhanced security, helping you to avoid costly incidents. Covering five total trust service principles (TSPs): security, availability, processing integrity, confidentiality, and privacy.

Monitor long and short-term corrosion rates and analyze data in real-time as it’s collected.

This feature allows you to analyze inspection and work history to maximize efficiency.

Connect with us to discuss tailored solutions

for your operational needs.